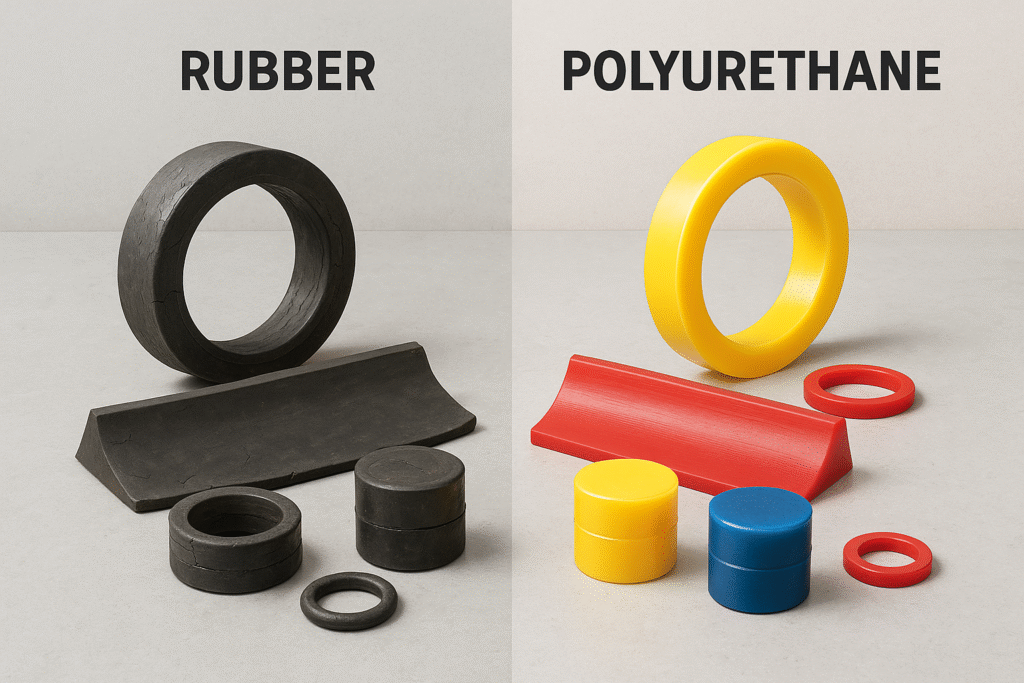

Rubber: A Traditional Material with Clear Limitations

Rubber has long been used in industrial machinery due to its flexibility, elasticity, and relatively low cost. It’s commonly found in seals, protective skirts, dampers, and other vibration-dampening components. However, rubber also has clear limitations: it wears out quickly under mechanical stress, degrades when exposed to oils, greases, or aggressive chemicals, and loses its properties in extreme temperatures.

Polyurethane: A Modern Solution for Demanding Conditions

Polyurethane is increasingly replacing rubber in many industrial applications. This modern material offers excellent abrasion and chemical resistance, along with superior durability in both high and low temperatures. Components such as polyurethane bushings, rollers, scraper blades, suction flaps, and vibration pads often deliver much longer service life than their rubber equivalents. Another key benefit is its customizable hardness — polyurethane can be precisely tailored to the needs of specific machinery or applications.

When Should You Choose Polyurethane Instead of Rubber?

Choosing the right material depends on several factors:

- High mechanical load or friction – Polyurethane performs better in heavy-duty conditions.

- Contact with oils, greases, or chemicals – Polyurethane offers higher chemical resistance.

- Extreme temperatures – Polyurethane remains stable over a wider temperature range.

- Cost-effectiveness in the long run – Even though polyurethane parts may have a higher initial price, they often save money due to longer lifespan and fewer machine downtimes.

While rubber remains a suitable option for less demanding uses where cost is critical, polyurethane frequently proves to be a smart investment in industrial machinery, minimizing maintenance costs and extending equipment service life.

PU Components – Your Partner for Custom Polyurethane Parts

At PU Components, we specialize in manufacturing custom polyurethane components for diverse industries, including heavy industry, automotive, municipal services, and even military applications. Whether you’re considering switching from rubber to polyurethane or need advice on optimizing your machinery parts, our team is ready to help. Get in touch with us to discuss how polyurethane solutions can improve the performance and durability of your equipment.